Mill owners regularly inspect the surfaces inside paper tanks, looking for damage to the welds such as rust, scratching, or pitting that might have developed since the last inspection. These inspections are not mandated by law but are done to ensure that the tanks stay in good condition to avoid the costs of unexpected downtimes.

Typically, a paper mill tank inspection is conducted by an inspector entering the tank and collecting visual data directly. This approach requires the plant to build scaffolding inside the tank so that inspectors can see every part of it up close. But building and taking down scaffolding is expensive and time consuming and can extend the downtime needed for the tank inspection by as much as two extra days.

Every hour the tank is down costs the mill $20,000 Euros. If the owners could use an indoor drone to collect visual data inside the tank, they could potentially save a lot of money by eliminating the downtime needed for building scaffolding. To test this approach, the mill hired Markus Rockenschaub to use the Elios 2 to inspect one of its tanks.

Testing the Elios 2

The tank Rockenschaub inspected at the mill is used to recycle old paper by mixing it with water as part of the paper-creation process. To conduct the inspection, he worked with a welding expert who was a specialist in these kinds of tanks. As Rockenschaub flew inside the tank, the specialist looked at the drone’s video feed on a large screen, identifying potential defects and other areas of interest.

After the mission, the specialist reported that he was able to see everything he needed for his inspection work just as well as if he had been standing inside the tank.

Using the Elios 2, Rockenschaub was able to fly inside the paper mill tank and identify:

- Scratches and pitting on its surface, which indicated that some of the surface needed to be renewed.

- Rust on the surface of the tank’s roof.

- Rust and heavy damage to the pillars of the roof.

- Damage to welds inside the tank.

Benefits of the Elios 2

Here are the benefits the mill realised by using the Elios 2 for the tank inspection:

- Savings. $960,000 Euros were saved by reducing the downtime required for the inspection by two full days.

- High quality data. The images and video the Elios 2 captured were of such high quality that they completely replaced the need for direct visual data collection inside the tank.

- Reduced downtime. The overall time required for the inspection was reduced from five days (2 days building scaffolding, one day inspection, 2 days remove scaffolding) to six hours.

The first test was so successful that the mill hired Rockenschaub to conduct its tank inspections going forward, permanently changing how it conducted these kinds of inspections.

Switching to Inspector 3.0

A year after that first inspection flight, Rockenschaub wanted to test Flyabilty’s new Inspector 3.0 software at the paper mill to see if it could help improve the tank inspection process even further.

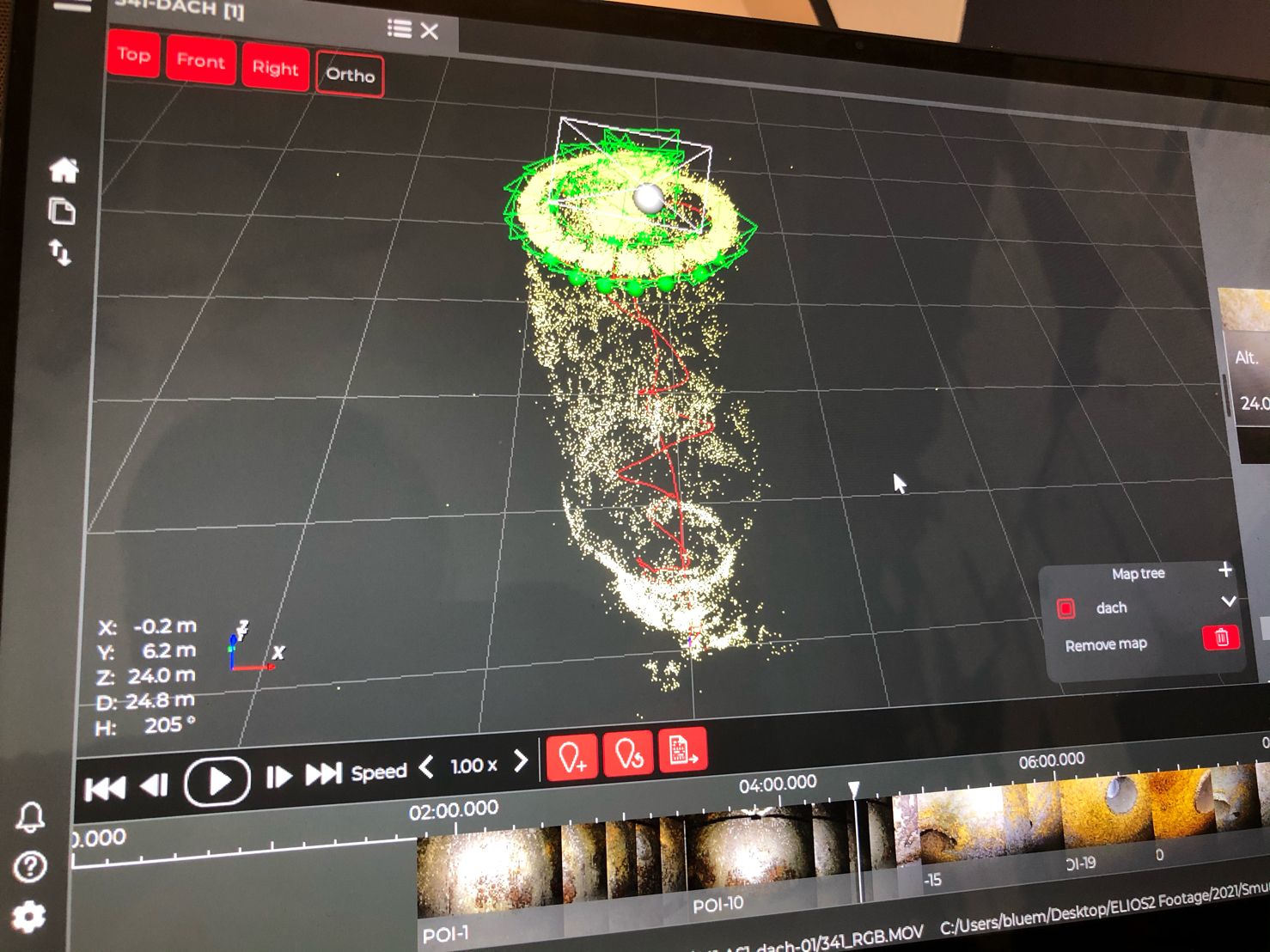

Inspector 3.0 allows inspectors to pinpoint the location of defects they identify in visual footage within a sparse point cloud of the asset they’re inspecting. This localisation data can then be shared with other members of the maintenance team, so they can know exactly where defects are located within an asset.

Using Inspector 3.0, Rockenschaub found that he could take the data collected with the Elios 2 and show the specific location of a defect within the paper mill tank. This locational data was coupled with visuals of the defect within the software (see example below), helping the paper mill’s maintenance team better understand the work that might need to be performed.

Source: Flyability