A major utility contractor in New South Wales conduct power line inspections with both helicopter surveying and ground-based methods, which took time and was expensive. They needed a more efficient and safer solution for inspecting power lines and energy assets across a remote and rugged landscape.

Brief

The major utility contractor’s existing methods for inspecting power lines involved helicopter surveys and ground-based teams, both of which were time-consuming, costly and posed significant safety risks. They needed a drone solution that could provide detailed visual and thermal data for preventative maintenance and fault detection over vast distances.

Key requirements included:

- Thermal and RGB imaging: The ability to detect overheating components and capture high-resolution imagery of power lines and infrastructure.

- Long-range inspections: A platform capable of covering large distances while maintaining consistent data capture.

- Repeatable results: A solution that can take identical shots during each inspection for easy cross referencing.

- High precision: The need for precise, real-time data to spot faults and anomalies accurately.

- Weather resistance: A platform that could withstand the harsh weather conditions commonly encountered in the region.

- Efficiency and safety: Reducing the time and risk involved with helicopter surveys while still gathering actionable data.

Existing Method

Previously, the utility contractor relied on helicopters and ground crews to inspect power lines, which proved inefficient and dangerous, especially in remote or high-risk areas.

- High operational costs: Helicopter inspections required significant financial investment.

- Safety concerns: Operating helicopters over mountainous terrain presented risks to crews.

- Limited efficiency: Helicopters were constrained by weather and daylight hours, causing delays.

- Data limitations: The data collected was often incomplete due to visibility issues and access limitations in difficult terrain.

Solution

Choosing the drone

After consultation with the experienced Sphere Drones team, the utility contractor selected the DJI Matrice 350 RTK as the drone platform of choice. The M350 RTK provided the long flight times, transmission range, and weather resilience required to cover vast sections of their powerline network.

About the DJI Matrice 350 RTK

The DJI Matrice 350 RTK is an advanced drone platform that redefines industry standards with its cutting-edge technology and versatility. Featuring an upgraded video transmission system, enhanced control experience, and a more efficient battery system, making it ideal for extended and demanding operations.

Key specs

- 55-minute flight time: Supports long-duration missions, covering extended distances without frequent battery changes.

- 20km transmission range: Ensures reliable data transmission over large inspection areas, crucial for remote asset coverage.

- Advanced safety features: Multi-sensor redundancy and obstacle detection provided added safety during flights over difficult terrain.

- IP55-rated weather resistance: Allows for all-weather inspections, a key advantage given the challenging environmental conditions in the region.

Choosing the payload

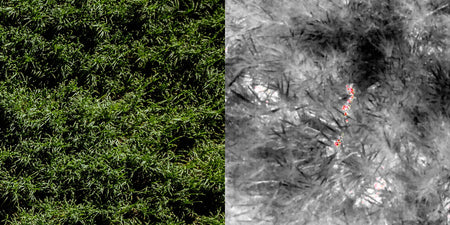

For detailed thermal and RGB data capture, the DJI Zenmuse H30T payload was the perfect fit. Its combined high-resolution zoom, wide-angle camera, and high resolution thermal capabilities enabled the team to spot issues such as overheating conductors, damaged insulators, and other infrastructure problems without the need for close-range inspections.

About the DJI Zenmuse H30T

The H30T payload offers the perfect balance of thermal imaging and high-quality RGB, making it an ideal tool for powerline inspections. Its 400x hybrid zoom allows for capturing fine details from a safe distance, while the thermal camera can identify heat-related issues on the power delivery infrastructure.

Key specs

- 400x hybrid zoom: Captures high-resolution images of power lines from a safe distance.

- Thermal imaging: Identifies hotspots or faulty components by detecting temperature variations.

- Wide-angle camera: The 48MP camera gives a broad overview of the infrastructure, ensuring all angles are covered.

- Laser Rangefinder: Measures distances up to 3,000 metres for efficient and safe flight planning.

Choosing the software

The customer integrated DJI Terra into their workflow for processing and analysing the data collected from the M350 and H30T. DJI Terra’s ability to handle both thermal and visual data enabled the utility contractor to generate detailed inspection reports quickly and accurately.

About DJI Terra

DJI Terra facilitates rapid post-processing of the visual and thermal data collected during the inspections, enabling users to generate 3D reconstructions and detailed orthomosaic maps. This allows teams to identify problem areas on power lines with greater accuracy and plan maintenance accordingly.

Result

Following the deployment of the M350 RTK and Zenmuse H30T, the utility contractor was able to streamline their inspection process significantly, saving them time, costs and improving safety for their staff. The combination of long flight times, high-resolution thermal and visual data, and real-time feedback allowed the company to identify issues more efficiently while reducing the need for manual inspections.

Key improvements include:

- Increased efficiency: The drone-based solution reduced inspection times, allowing for faster identification of issues along power lines.

- Cost savings: The shift from helicopter inspections to drone-based operations provided operational cost savings while maintaining high data quality.

- Improved safety: By replacing helicopter flights with drone inspections, the company reduced risks to personnel working in hazardous areas.

- Enhanced fault detection: The use of thermal and high-resolution RGB imagery enabled more accurate detection of potential faults in the power infrastructure.

- Consistent data quality: The H30T’s ability to capture high-resolution images and thermal data ensured that critical infrastructure was thoroughly inspected.