Situation

Located in PNG, the K92 mining operation team was keen to implement a commercial drone program to help manage key operating tasks that would not only improve the efficiency and indeed, productivity of their operations, but also limit their personnel being put in harm’s way.

Having seen global mining operations successfully implement commercial drone programs, the mine operators selected key K92 personnel to be trained on drone activities including surveying stockpiles, haul roads and structures.

The training included how to operate the Phantom 4 RTK RPAS as well as securing an understanding of the workflow for drone 3D mapping.

The end goal of workshops was for the operators to have a sound understanding of drone operation to the point whereby they could, independently, produce survey grade point clouds and 3D surface models.

Requirements

Leading Australian drone enterprise and commercial solutions provider Sphere Drones was selected to provide this offshore training given their experience and position as one of Australasia’s preeminent drone enterprise organisations. An experienced operations training specialist was deployed to PNG, making the journey to the K92 mine site to assist with the roll out of their drone program.

Solution

Two workshops were provided to the group. The first being a preliminary session on general drone operations. This included:

Basic components of a drone including aerodynamics and flight performance

- Operating requirements + pre/post flight checks

- Situational awareness

- Personal capability

- Risk assessment

- Maintenance

These fundamentals were designed to give the new operators a sound understanding of key drone operational workflows with an emphasis on safety and efficiency.

The second session was more specific to their application and provided comprehensive training on 3D mapping – an essential element in mine site management. This included:

- Basics of photogrammetry

- Workflow for 3D mapping

- Mission planning best practices, recommended settings, tips and tricks

- Ground control points (GCP). What are they? How are they used?

- Post processing basics (using Pix4D software)

- Basic point cloud editing and generating ortho mosaics and DTMs (Pix4D)

On-site engagement

The training was undertaken over 3 intensive days:

Day 1:

- The Sphere team provided a comprehensive introduction to drones and drone technology including detailing the drone equipment, updating of firmware (despite bandwidth limitations!) and ensuring fully compatible devices (RC, RPA & D-RTK2).

- Manual flight training was also undertaken and, as it happened, eagles were present in the sky adding a significant challenge to the new pilots. The good news was collisions were avoided and the pilots learned a valuable lesson on the importance of manual flight training and competency even during autonomous missions.

- As part of the flight training, the new pilots were then given a full workflow demonstration including planning, capturing and processing data.

Day 2:

- Training included a review of the previous day’s outcomes (that had been processed overnight). Using ground control points (GCP) and checkpoints (CP), the new operators were educated in assessing the accuracy of the model as well as being able to produce a point cloud to use within their local software for design and assessment.

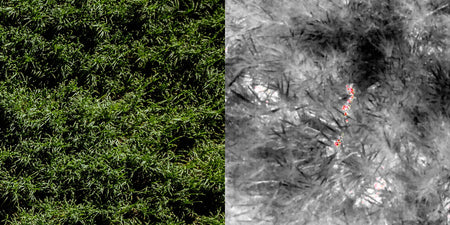

- A mission plan was then set up for 2 sites. The first, their tailings storage facility (a slurry dam) and second, their 800 portal (the entrance to their underground operations). Key challenges included the extreme changes in elevation combined with having no map tiles available in the GSRTK app. To facilitate this, a KML was created in Google Earth Pro and the drones flew above the take off point to ensure there was enough overlap to cover the top of the hills and avoid collision risk.

- The training also included utilising the Terrain Awareness feature in the P4RTK after producing the Digital Surface Model (DSM) from the initial flight. In challenging terrain such as where the K92 mine is located; this feature is essential.

- The final activity was capturing the tailings storage facility (TSF) and then having the trainees process the collected images through Pix4D software.

Day 3:

- The new pilots were tasked with flying the 800 Portal site and its stockpiles. Until this time, the stockpiles were measured by physically walking the piles themselves – a high risk and time-consuming exercise to get volume measurements. With the drones in action, the new pilots secured an appreciation for the efficiency, speed and safety gains that could be achieved with the drones in less than an hour.

- All three surveyors/new pilots successfully completed the full workflow program so were able to be signed off as independent and competent RPAS operators. To make the process easier after our departure, a workflow document for 3D mapping with P4RTK and Pix4D was provided. This has proven itself an invaluable tool for operational independence.

Results

The workshop results were self-evident. The select K92 team now have the skills to safely and effectively operate RPAs independently across their sites.

They demonstrated the capability to successfully complete an RPAS based photogrammetry workflow including mission planning and data capture in addition to post processing basics such as orthomosaic generation, basic point cloud editing, generation of 3D maps and DTMs.

For additional information on this case study, please contact the Sphere Drones Team at info@spheredrones.com