SIMEC, an international energy and natural resources business, sought to develop a drone lead solution to calculate the volume of their coal stockpiles.

Brief

Tahmoor Mine is an underground coal mining operation situated in the Southern Highlands of New South Wales. The majority of its product is hard coking coal as well as small amounts of steaming blend coal. The coking coal is used for steel making and the steaming blend coal used for power generation.

In 2018, SIMEC Mining purchased the coal mining operations from Glencore. As part of on-going operations, SIMEC approached Sphere Drones to develop an easier, less labour intensive and more cost effective method of calculating the volume of their coal stockpiles.

Volume calculations for coal mines are extremely important given the market volatility of price. With accurate stockpile volumes, the operators and indeed, shareholders can see the running market value.

The current calculation method required surveyors to physically measure the stockpile from ground and base surveying techniques. This method is slow, lacks data detail, is prohibitively expensive and carries inherent safety risks through machine and human interaction.

In simple terms, SIMEC needed an easier, safer and more cost effective solution where they could conduct these calculations in-house and secure more accurate data without contracting surveyors.

Solution

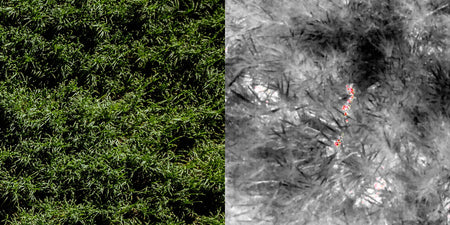

Sphere Drones visited the SIMEC coal mine. After a comprehensive review of their needs, the Phantom 4 Pro drone was proposed as the solution for their purposes given the size of the area they needed to map. Because volumetric calculations don’t require high end imagery (such as surveyors using photogrammetry), the 1-inch sensor on the Phantom 4 Pro produced enough detail to utilise the functionality within the processing software.

From this information we utilised Pix4D to create a 3D map of the stockpiles, and through the scope and functionality of the software, we removed stationary equipment such as the conveyor belts to clearly view the stockpiles which allowed for accurate measurement of their volumes. To add certainty, we conducted visual 3D fly throughs which also offered stockpile views from above.

Result

SIMEC are now processing all of their surveying needs in-house and without the need for contractors saving substantial costs. They also now have the tools and training to undertake all necessary stockpile volume calculations and, if required, are positioned to be able to upgrade their drone package should they choose to conduct high-end photogrammetric processes.