Reflecting on 2019, the Sphere Drones operations team worked all over Australia with a wide range of our clients in mining, agriculture, oil and gas and environmental research.

A big focus of our travel plans and site-visits are to demonstrate to management and end-users how drone technology can be utilised on-site to increase safety, efficiency and overall business improvements.

In this post, we dial in on a site-visit to demonstrate the Flyability Elios 2 to a coal mining company in Northern NSW.

Having spent time with their maintenance and survey teams, it became apparent that there was a clear desire on their behalf to enhance the way they perform confined space inspections’ on their large coal bins.

The main reason for this? Safety and cost. Traditionally, coal bins are generally inspected in the following way:

- The bin is ‘shut down’, making it non-operational (costs for this shut down go into the thousands of dollars per hour)

- The bin is then hosed down with water, washing away any excess coal and dust that may be inside.

- Scaffolding is set-up inside, usually from the bottom up (the bins can be up to 70m high)

- People then get inside to inspect the area, searching for missing / damaged tiles, as-well as general condition of the walls. Quite a dangerous and unpleasant way of performing an inspection.

Without seeing the quality of the bin before entering, the inspection needs to be thorough. This means the inspection process can take anywhere from 24-72 hours per bin with the risk of injury to personnel being high during this period (not to mention the cost).

Being very excited and eager to show our client how this process could be improved using the latest Flyability Elios 2, we traveled to their site with the objective of identifying missing and broken tiles that are just too difficult to see from the outside.

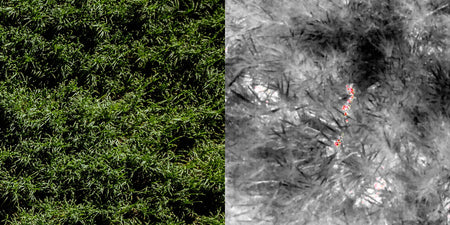

With a flight time of up to 10 minutes we were able to perform successful missions in half that time, identifying tiles that needed to be repaired or replaced. With 10k lumens lighting and a 4K camera streaming HD live to a secondary tablet, we were able to identify these tiles mid-flight, giving our client instant feedback on the quality of their coal bin.

In just a couple of flights with the help of our client’s maintenance team, we were able to identify and understand the extent and location of the damaged tiles. With this information, the maintenance team is able to cut the time spent inside the coal bins by more than half as they don’t need to inspect the whole bin, they can get inside, make the repairs and get out.

The benefit of this? Once again, safety. Having reduced the time people spend in confined spaces by more than half, an investment into having an Elios 2 on-site made absolute sense as it results in an increase in productivity and a safer working environment.