Our manufacturing team developed the drop mechanism as a solution to help our customers safely release packages and drop lines in a controlled manner using a drone.

Developing the drop mechanism

When creating the drop mechanism, our team had three key objectives:

- Ensure the drop mechanism can safely release payloads

- Make it integrable with the Matrice 300's existing mounting points

- Test extensively to validate the reliability and release precision

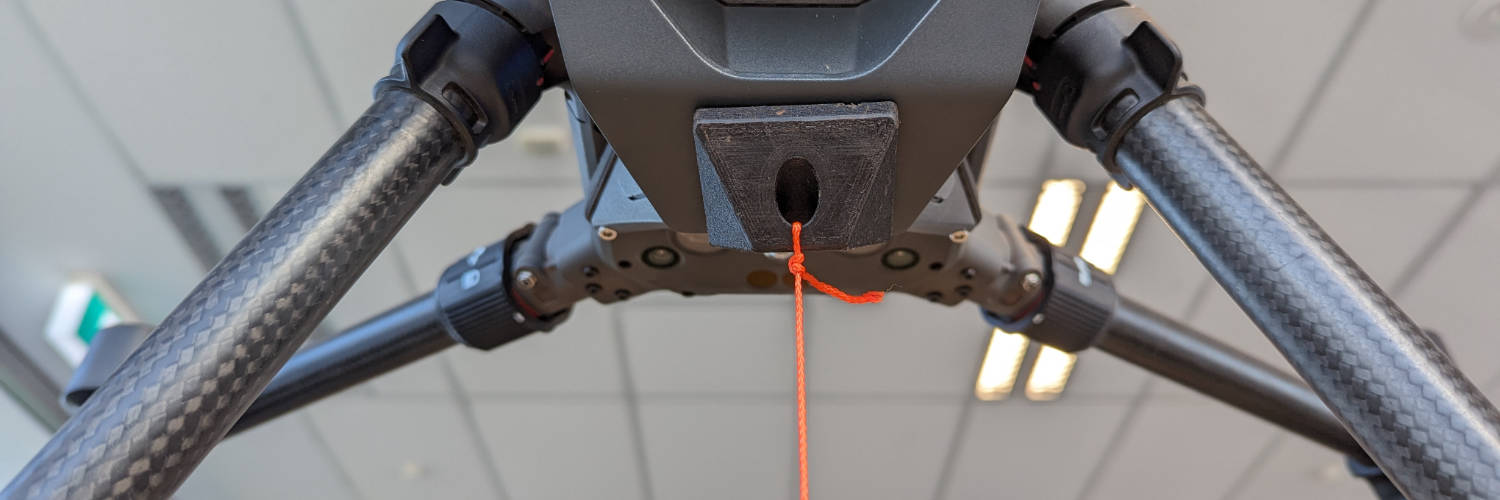

The drop mechanism our team ended on consists of a small main body produced out of lightweight carbon fibre and aluminium that mounts flush to the DJI Matrice 300 in order to maintain the aerodynamic profile of the drone.

Using drop mechanism

Our drop mechanism features its own drone-independent battery that charges via USB-C. On the drop mechanism itself, there is an arm and disarm button, allowing for payloads to be mounted and unmounted without requiring a controller.

When the drop mechanism is loaded and the drone is in the air, the drop mechanism connects to a small add-on, that mounts to your drone's controller, or any USB-A power source.

The add-on controller features a small screen that displays the current status of the drop mechanism and the amount of resistance on the mechanism itself. On top, there is the release button, hidden under a cap to prevent accidental releases.

Benefits of the drop mechanism

After using the drop mechanism with numerous clients in the field, the benefits of using the drop mechanism over traditional tools and methods (specifically with line stringing operations) were apparent, including:

Increased efficiency

The drop mechanism allows line stringing to be done in a fraction of the time with less people required.

Increased safety

Instead of placing employees in a potentially dangerous environment, the drop mechanism allows employees to maintain a safe distance.