Conveyor belts and mining equipment in general are the lifeline of mining operations, from moving material to processing and transporting material. All this equipment requires regular inspections, maintenance, and repairs often resulting in downtime and creating dangerous environments.

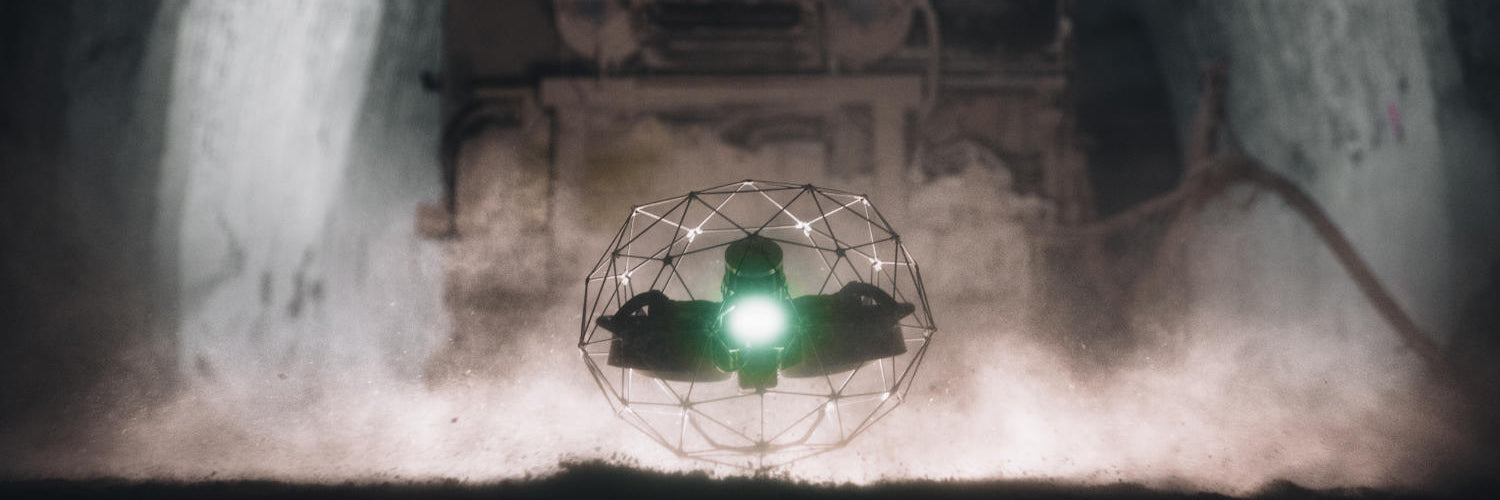

Flyability's Elios 3 drone is the perfect solution for this.

Mining equipment inspection with Flyability Elios 3

Using Elios 3 is super simple thanks to the simple-to-use controller equipped with a tablet for a live feed from the drone. Elios 3 is equipped with a LIDAR unit that creates a live 3D map of the operational area for improved situational awareness and much better stability.

Thanks to the core flight improvements of Elios 3 pilots can focus on the operation more, which means improved data capture and decision making. Elios 3's inspection payload features an RGB and thermal camera, distance sensor, and lighting system allowing for clear images of assets backed up with a 3D digital twin captured with the LIDAR unit.

Data captured on Elios 3 can be transferred into Flyability's own Inspector 4.0 software or imported into GeoSLAM's software platform for further investigation.

Benefits of using Flyability Elios 3

- Collision resilient - Elios 3's collision resilient design, bumping into the conveyor belt or ore doesn't mean a broken drone. Elios 3 continues to fly and allows the operation to be completed.

- Reduced downtime - Elios 3 size and collision resilient design means it can inspect conveyor belts without any or minimised downtime.

- Cost savings - As a result of increased efficiency and reduced downtime inspection and downtime related costs are heavily reduced.

- Improved health and safety - Personal no longer have to manually inspect conveyor belts, removing exposure to potential pinch points, lose ore, and major injuries.